With 2023 now drawing to its inevitable close, I thought I’d take a moment to look forward to the year ahead and see what we have in store for 2024. We do have several very interesting projects that are not far enough along to make any public statements about just yet, but as soon as it’s appropriate to do so, I’ll make those announcements separately.

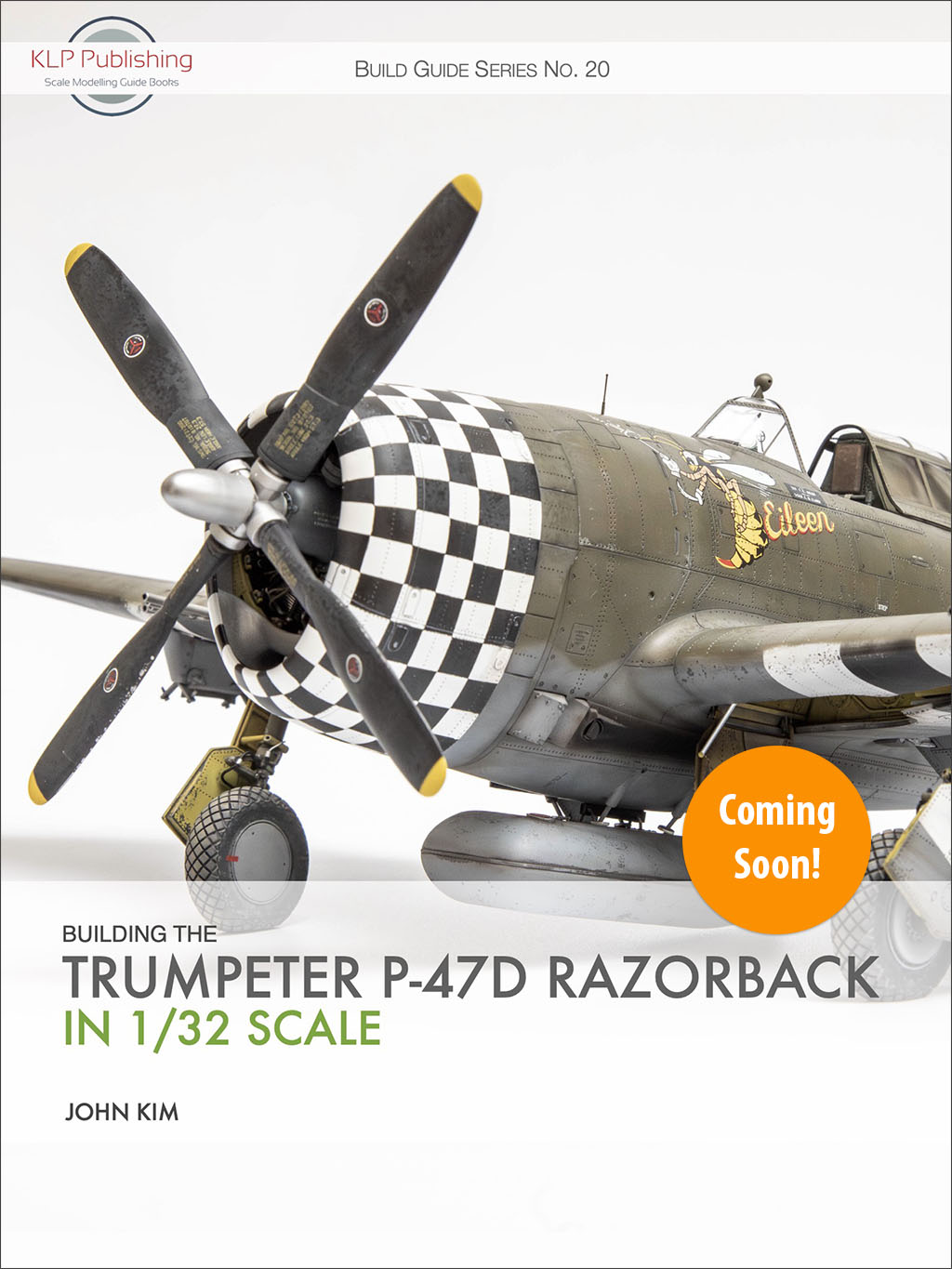

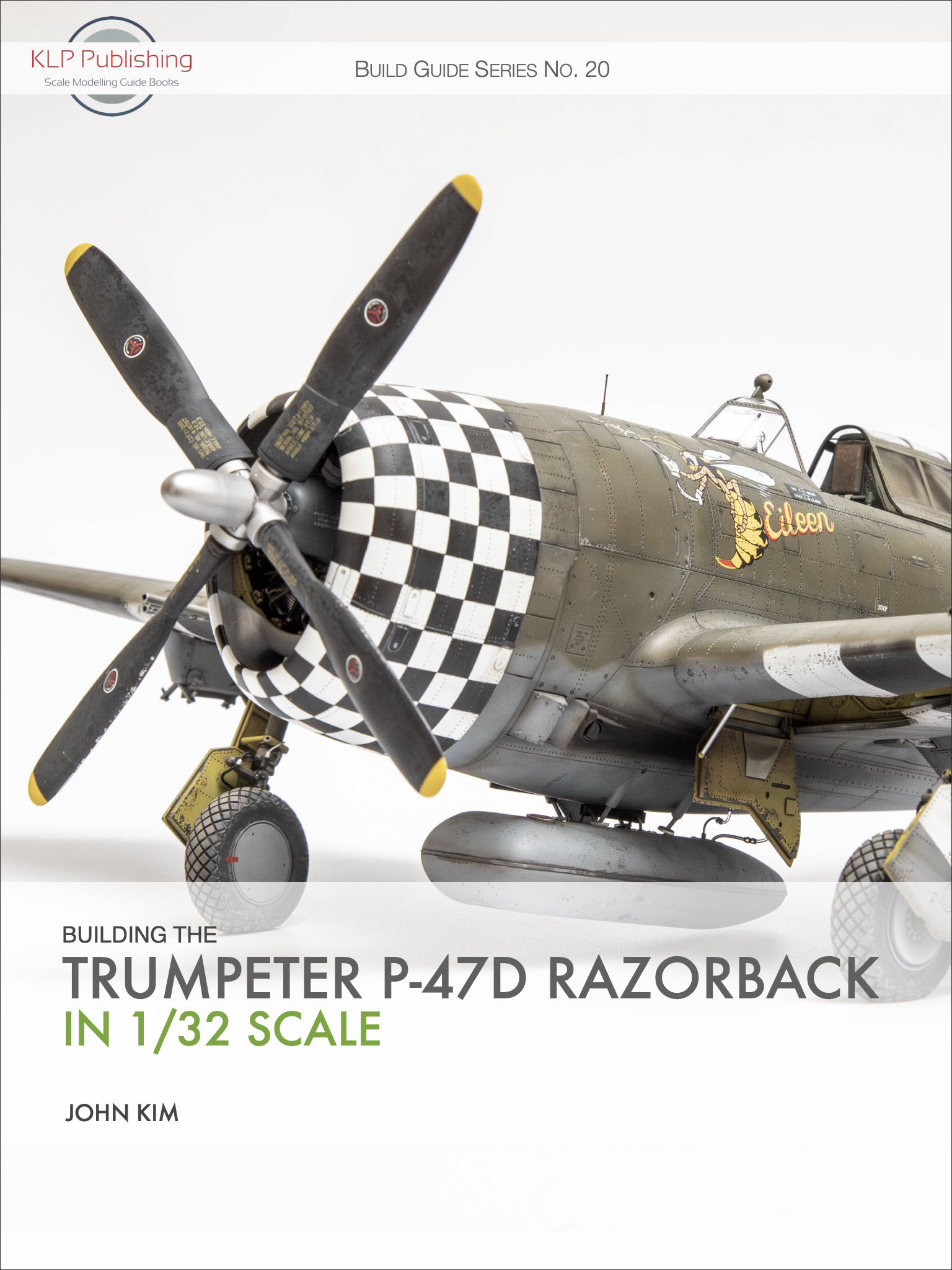

But of our confirmed, scheduled projects, first cab off the rank is John Kim‘s Building the Trumpeter P-47D Razorback in 1/32 Scale:

This is currently undergoing proofing and revision, and should be available by the middle of January.

Next up will be Geoff Coughlin‘s build of the new Airfix 1/48 Sea King for Build Guide Series No. 21:

Work will be getting under way on this one shortly!

There’s a strong possibility that one of our unnamed projects will come next, and it will be closer in style to our Phantom series than a straight modelling guide. Failing that, it will most likely be a book that was actually planned for 2023, but failed to make the release schedule:

The recent news that Zimi Model plans to re-release the Kitty Hawk range should see the Texan/Harvard kits available once again (if not already), and Chuck Sawyer‘s build guide will be the perfect companion. (Note that the cover is subject to change prior to publication.)

The release schedule for the rest of 2024 is less certain, and largely dependent on when various projects come to fruition. But look out for a Build Guide on the Wingnut Wings Fokker D.VII series by Gary Boxall, a second volume of sci-fi & fantasy builds by Jason Gares, at least one more Build Guide from John Kim, and others covering the ICM 1/32 Yak-9 and Zoukei-Mura 1/32 Skyraider.

We also have other projects under negotiation or development, that—again—aren’t quite ready for a public unveiling. But stay tuned for all our usual announcements and updates as they come to hand!

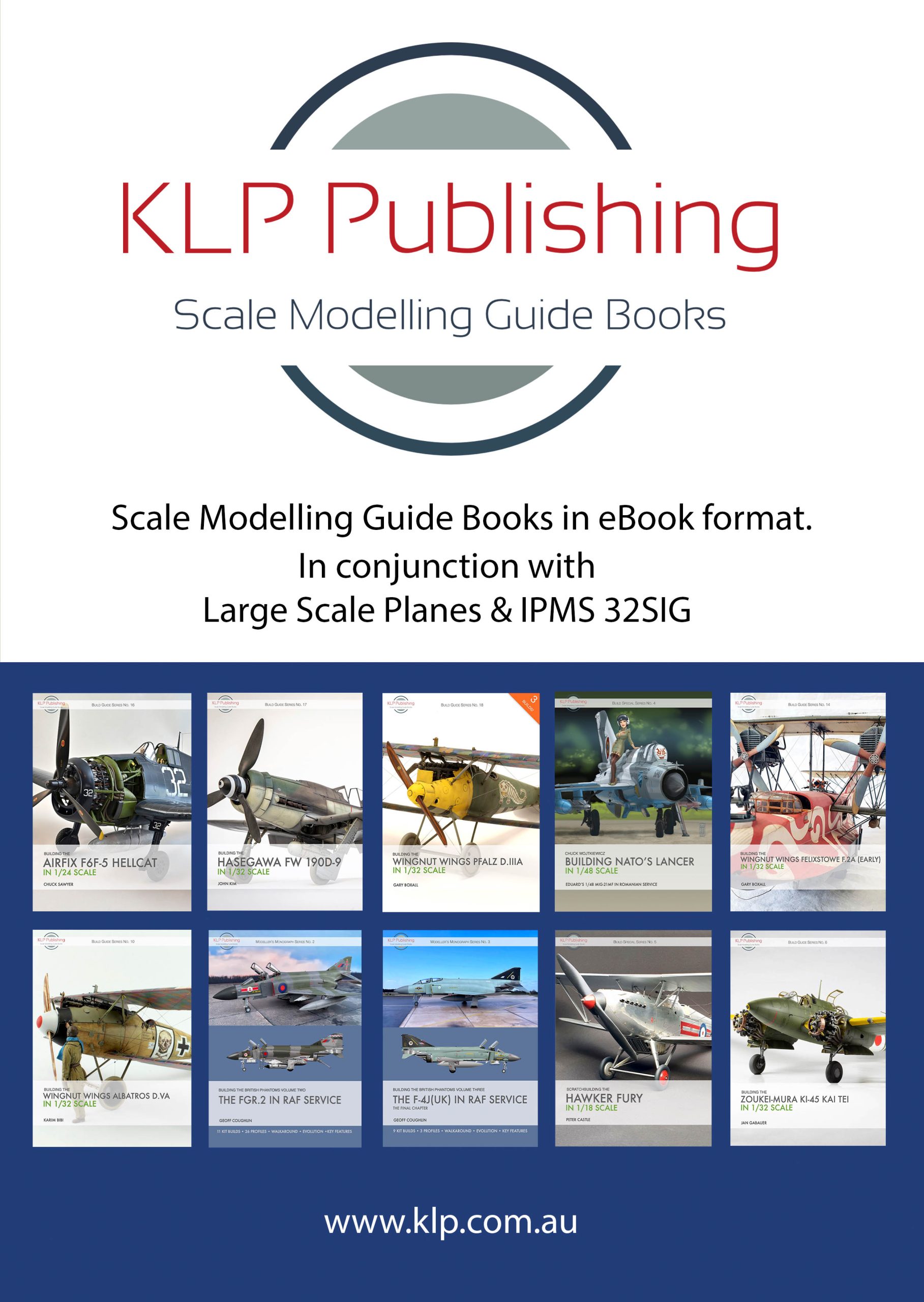

As for 2023, we managed to publish the following seven new titles:

-

Building the ICM D.H.82A Tiger Moth in 1/32 Scale$17.00

Building the ICM D.H.82A Tiger Moth in 1/32 Scale$17.00 -

Building the British Phantoms Volume Three: The F-4J(UK) in RAF Service$20.00

Building the British Phantoms Volume Three: The F-4J(UK) in RAF Service$20.00 -

Scratchbuilding the Hawker Fury in 1/18 Scale$20.00

Scratchbuilding the Hawker Fury in 1/18 Scale$20.00 -

Building the Wingnut Wings Pfalz D.IIIa in 1/32 Scale$20.00

Building the Wingnut Wings Pfalz D.IIIa in 1/32 Scale$20.00 -

Building NATO’s LanceR in 1/48 Scale$16.00

Building NATO’s LanceR in 1/48 Scale$16.00 -

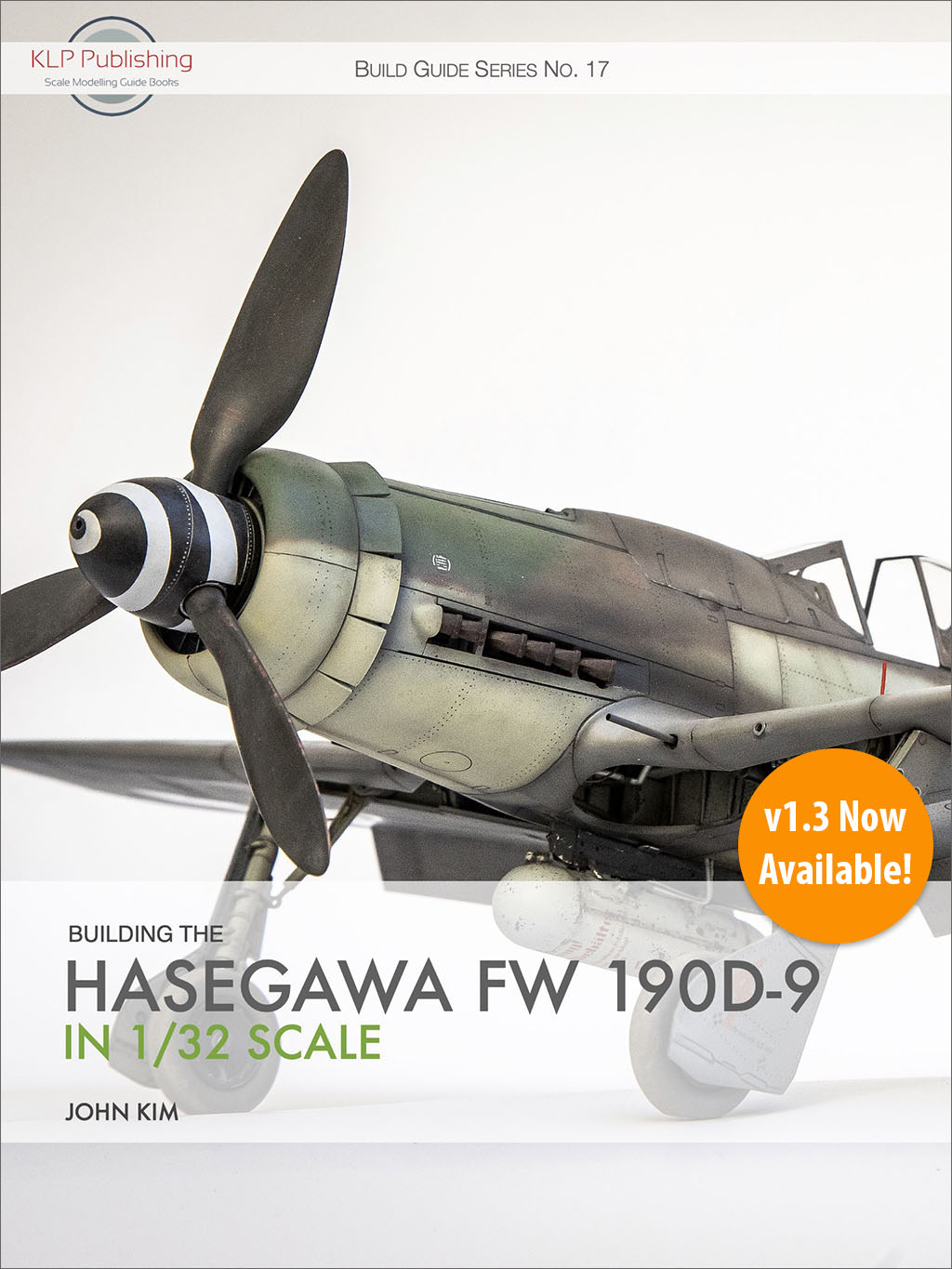

Building the Hasegawa Fw 190D-9 in 1/32 Scale$18.00

Building the Hasegawa Fw 190D-9 in 1/32 Scale$18.00 -

Building the British Phantoms Volume Two$22.00

Building the British Phantoms Volume Two$22.00

Many thanks to all our customers for a great year in 2023, and I wish you all a Happy New Year for 2024!

You must be logged in to post a comment.