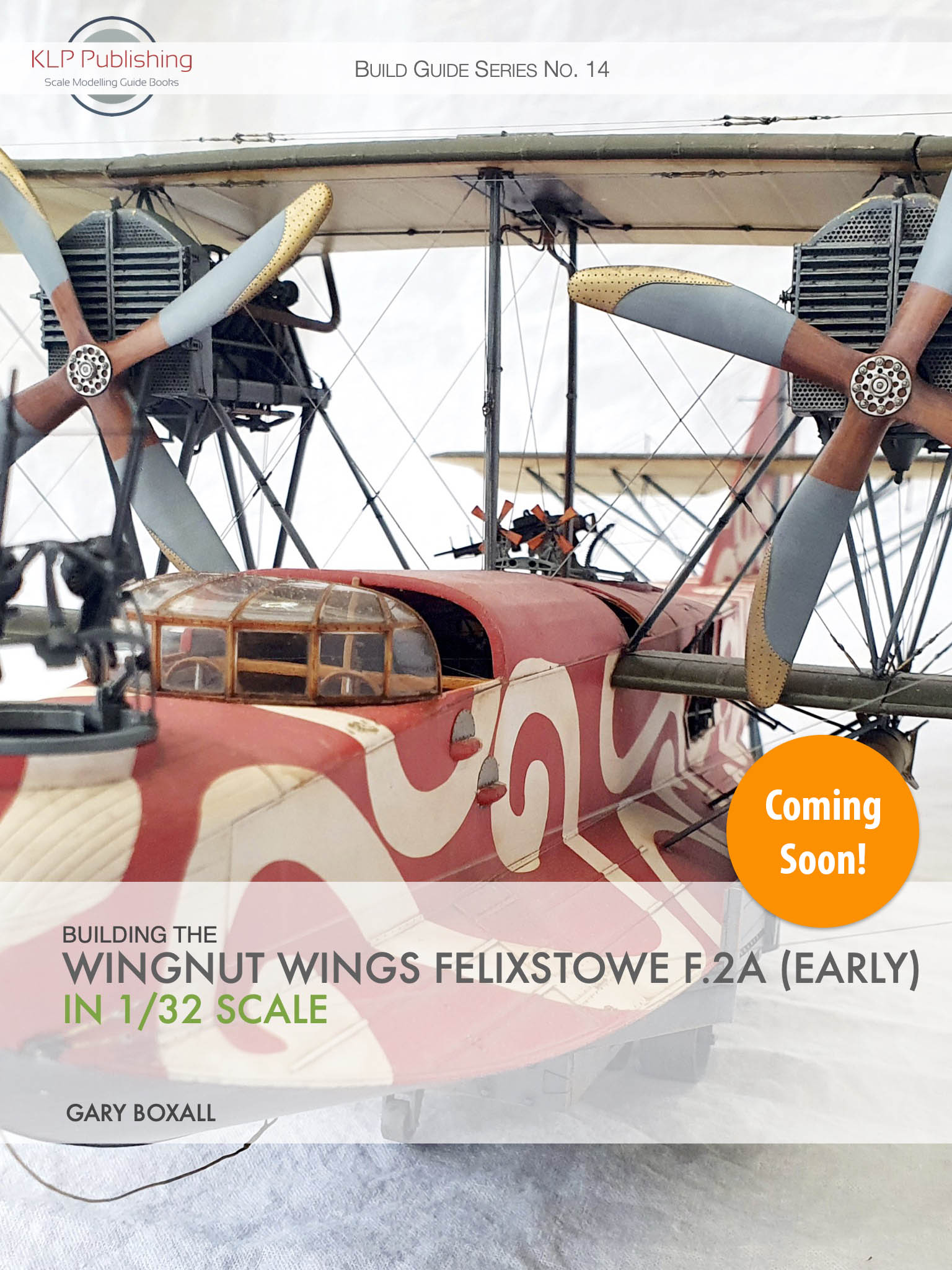

I’m pleased to announce that our latest title, Building the Wingnut Wings Felixstowe F.2A (Early) in 1/32 Scale, is now available!

In this 292-page eBook, Gary Boxall builds, paints, and rigs the giant Wingnut Wings 1/32 Felixstowe F.2A to an award-winning standard. While Gary’s build focusses on the ‘early’ boxing of the kit, his methods are equally applicable to the ‘late’ version, and we’ve included a great many photos of Gary’s rigging process to assist in this difficult area—helpful for anyone building any aircraft that requires even a modicum of rigging!

Gary also describes how he painted the interior, modified parts to be more accurate or more detailed, cut custom masks for the eye-popping ‘swirl’ paint scheme, and made templates for the Aviattic fabric decals that cover the wings and tailplane. And much more!

The book also includes a detailed look at the kit by Brett Green, and our usual Appendices covering available aftermarket and reference material.

And all this for just 17 Australian dollars!

Building the Wingnut Wings Felixstowe F.2A in 1/32 Scale

In this 298-page eBook, Gary Boxall builds, paints, and rigs the giant Wingnut Wings 1/32 Felixstowe F.2A to an award-winning standard. While Gary’s build focusses on the ‘early’ boxing of the kit, his methods are equally applicable to the ‘late’ version, including painting the interior, improving details, creating custom paint masks, making templates for the Aviattic fabric decals, and of course, rigging!

The book also includes a detailed look at the kit by Brett Green, and our usual Appendices covering available aftermarket and reference material.

v3.0 Now Available!

Note: all our prices are in Australian dollars.

$17.00

So head on over to our webshop and grab yourself a bargain.

You must be logged in to post a comment.