At the end of Part 9, we had the basic paint job done, and were ready for some painted-on markings and decals. Let’s get that done, and get this build over the line!

Since I had planned to paint the fuselage codes and serial numbers, but use decals for the national insignia, the first task was to get a nice gloss coat down in preparation. I appreciated that the whole gloss before decals thing is a contentious one on the modelling Internet these days, but I like to do it anyway as a bit of a security blanket. And the Model Master Olive Drab enamel paint I used had an especially flat and chalky finish.

The national markings are from a Fantasy Printshop set, but were a little bit brittle, so I experienced a bit of cracking here and there. The red demarcations on the flaps were masked and painted. You’ll note that I also painted the base of the antenna on the tail silver.

Next up, the fuselage codes were masked using the set I created and cut earlier using the Silhouette Portrait, and airbrushed with SMS White:

The aircraft name and a handful of stencil decals came from the kit sheet. They weren’t in great shape, so I kept their usage to an absolute minimum. There’s a bit of silvering and some wrinkling to deal with, but nothing a bit more decal solvent didn’t sort out.

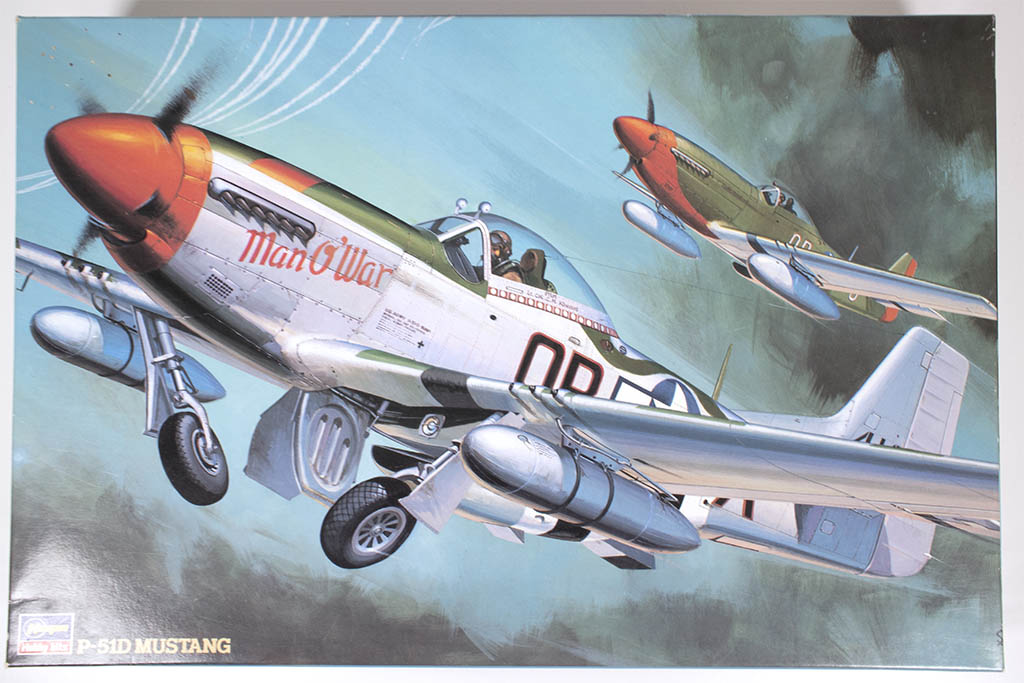

The serial numbers were masked and sprayed next, along with fitting the landing gear and prop. A flat coat chased most of the silvering away:

At this point I thought I had an easy ride to the finish line, but guess which dope forgot to remove the interior windscreen masks prior to gluing it into place on the fuselage… I made a right mess getting them out, and managed to knock the gun sight glass off in the process. No way of getting it back in, but at least I managed to remove most of the adhesive residue from inside the windscreen, and hide most of the scratches I made.

One last thing to address before I could call it done: the sliding portion of the canopy. It didn’t really fit properly in the closed position, so I’d have to pose it open (which was the plan all along). But it doesn’t sit properly when slid back, either! As the fuselage narrows towards the read of the cockpit, the front of the canopy obviously doesn’t pinch in to accommodate this, and so just drapes down over the fuselage. So I added a pair of short lengths of styrene strip to act as supports for the front of the sliding canopy:

These did the job admirably:

I painted them Interior Green to get them to blend in as much as possible, and they don’t really stand out on the finished model. You’ll note that I also added a rear-view mirror to the top of the windscreen, which I borrowed from the Tamiya kit, after determining the correct style.

After fitting the final fiddly bits, it was finally done!

Thanks to everybody for following along, and I hope the result meets with your approval. If you’d like to read a much more in-depth account of the process, check out my build thread over on the Large Scale Planes forums.

Until the next one!

You must be logged in to post a comment.